-40%

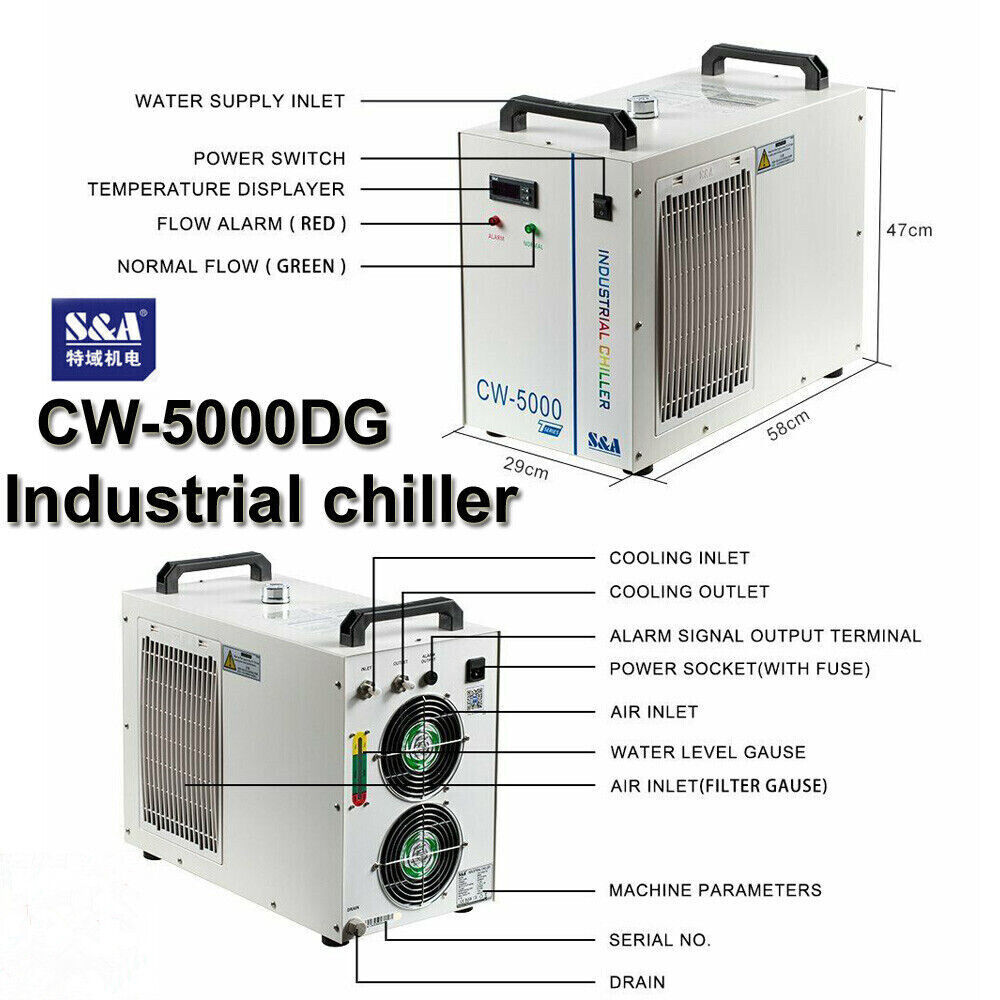

S&A Water Chiller 5000TG Industry Cooling System for 100W-130W Laser Machine US

$ 279.31

- Description

- Size Guide

Description

S&A CW5000TG Industry Cooling Water Chiller for CO2 Laser Machine 220V USThe CW-5000 Chiller is popular for cooling CNC and Laser machines.It is designed for cooling the one CO2 glass laser tube under 80W/100W of the laser engraving and cutting machine. Emitting rate higher than 60%.Under normal circumstance,the new intelligent

temperature controller does not need to adjust the controlling parameters.

Features:

1.±0.3℃ precisely temperature control

2.800W cooling capacity; use environmental refrigerant

3.Compact size, long working life and simple operation

4.The intelligent temperature controller has 2 control modes, applicable to different applied occasions; with various setting and display functions

5.Multiple alarm functions: compressor time-delay protection, compressor overcurrent protection, water flow alarm and over high / low temperature alarm.

Specification:

Name: CW-5000 Chiller

Voltage: 220V/110V(please leave message to tell us your voltage)

Frequence: 60HZ

Current: 3.5~5.6A

Tank Capacity: 6L

Compressor Power: 0.305KW, 0.41HP

Refrigerating Capacity: 2866Btu/h, 0.84KW, 722Kcal/h

Refrigerant: R-134a

Refrigerant Charge: 280g

Precision: ±0.3℃

Reducer: Capillary

Pump Power: 0.03KW

Maximum Flow: 10L/min

Maximum Pumping Lift: 10M

Inlet and Outlet: External Φ10mm brass connector

Protection: Flow alarm

Install steps:

A.Open the package to check if the machine is intact and all the necessary accessories are completed

B. Open the injection port to feed cooling water

C. According to system conditions, please well connect water inlet and outlet pipe

D. Plug in, turn on the power switch. (Do not start up without water in the tank!)

E. Check the water level in the water tank

F. Adjust parameters of temperature controller